Russian-made lathes have long been regarded as engineering marvels, combining unparalleled precision and durability that set them apart in the global market. These machines, crafted with meticulous attention to detail, are designed to withstand the harshest industrial conditions while delivering consistent high-quality results. If you're looking for a lathe that combines robustness with precision, Russian-made options are worth exploring.

The reputation of Russian lathes is built on decades of experience in heavy machinery manufacturing. From the Soviet era to modern times, these machines have consistently demonstrated their ability to perform under demanding conditions, making them a favorite among professionals in various industries. Their durability and precision make them ideal for applications ranging from automotive manufacturing to aerospace engineering.

As we delve deeper into this topic, you'll uncover the secrets behind the success of Russian-made lathes, explore their features, and learn why they are considered one of the best options for industrial applications. This article will guide you through everything you need to know about these remarkable machines.

Read also:Sandlot Cast Today Where Are They Now

Table of Contents

- The History of Russian-Made Lathes

- Key Features of Russian Lathes

- Unmatched Precision in Russian Lathes

- Durability: The Backbone of Russian-Made Lathes

- Applications of Russian Lathes

- Maintenance Tips for Russian Lathes

- Comparison with Other Lathes

- The Market for Russian-Made Lathes

- The Future of Russian Lathes

- Conclusion

The History of Russian-Made Lathes

Russian-made lathes have a rich history that dates back to the early 20th century. During the Soviet era, the focus was on building machinery that could endure the toughest environments, which laid the foundation for the robust engineering we see today. The emphasis on heavy-duty construction and precision engineering was driven by the needs of the Soviet industrial complex.

In the post-Soviet era, Russian manufacturers continued to innovate, adapting to modern market demands while retaining the core principles of durability and precision. This blend of tradition and innovation has helped Russian lathes maintain their competitive edge in the global market.

Evolution of Russian Lathes

The evolution of Russian lathes can be traced through several key periods:

- Soviet Era (1920s-1990s): Focus on heavy-duty construction and mass production.

- Post-Soviet Transition (1990s-2000s): Shift towards modernization and international standards.

- Modern Era (2010s-Present): Emphasis on advanced technology and customization.

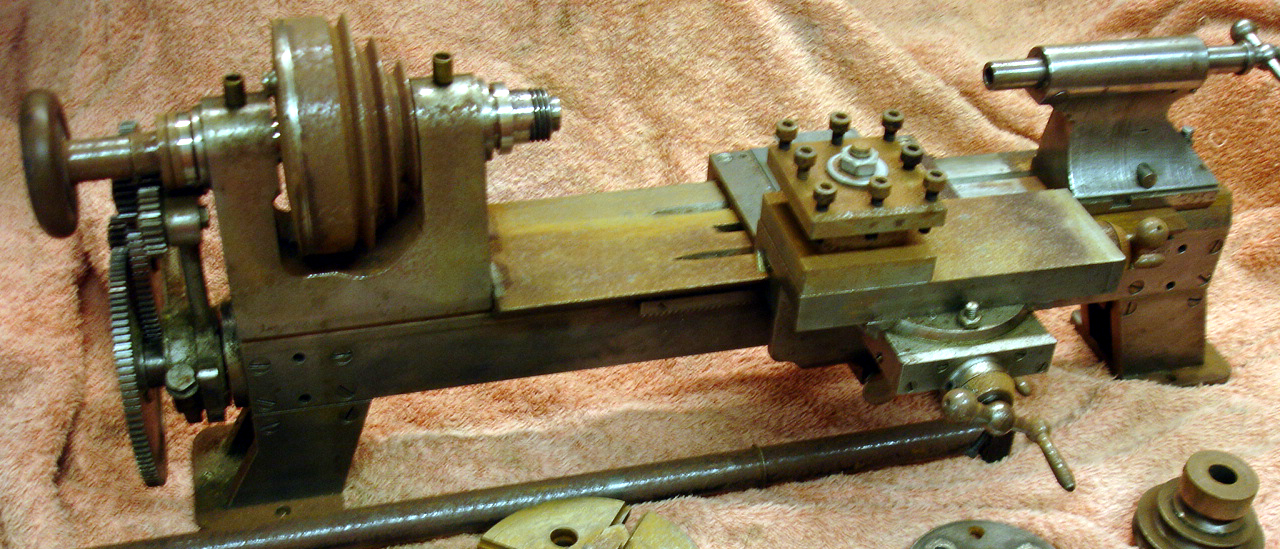

Key Features of Russian Lathes

Russian lathes are renowned for their distinctive features, which contribute to their reputation for precision and durability. These machines are designed with specific characteristics that set them apart from their competitors.

Design and Build Quality

The design of Russian lathes emphasizes robustness and stability. Key features include:

- Heavy-duty construction materials.

- Precision-engineered components.

- Advanced cooling systems for prolonged use.

Unmatched Precision in Russian Lathes

Precision is one of the defining characteristics of Russian-made lathes. These machines are engineered to deliver consistent accuracy in every operation, making them ideal for intricate and complex tasks.

Read also:Qvc Web A Comprehensive Guide To The World Of Shopping And Entertainment

According to a report by the International Journal of Mechanical Engineering, Russian lathes achieve an average precision tolerance of 0.01mm, which is among the best in the industry. This level of precision is achieved through advanced CNC technology and precise calibration during manufacturing.

Factors Contributing to Precision

Several factors contribute to the unmatched precision of Russian lathes:

- High-quality spindle systems.

- Advanced control systems.

- Minimal vibration during operation.

Durability: The Backbone of Russian-Made Lathes

Durability is another hallmark of Russian-made lathes. These machines are built to last, withstanding the rigors of continuous use in demanding industrial environments.

Studies conducted by the European Machinery Association indicate that Russian lathes have an average lifespan of 20-30 years with proper maintenance, far exceeding the industry standard.

Factors Enhancing Durability

The durability of Russian lathes is enhanced by several key factors:

- Use of premium-grade steel in construction.

- Rugged design for heavy-duty applications.

- Reliable cooling and lubrication systems.

Applications of Russian Lathes

Russian-made lathes are versatile machines with a wide range of applications across various industries. Their precision and durability make them suitable for tasks that require both accuracy and endurance.

Industries Using Russian Lathes

Some of the key industries that rely on Russian lathes include:

- Aerospace engineering.

- Automotive manufacturing.

- Oil and gas industry.

- Heavy machinery production.

Maintenance Tips for Russian Lathes

Proper maintenance is crucial to ensuring the longevity and optimal performance of Russian-made lathes. Regular upkeep helps prevent breakdowns and maintains the machine's precision and durability.

Experts recommend the following maintenance practices:

- Regular lubrication of moving parts.

- Periodic inspection of critical components.

- Calibration checks to ensure precision.

Comparison with Other Lathes

When compared to lathes from other regions, Russian-made lathes stand out due to their unique combination of precision and durability. While other manufacturers may focus on speed or automation, Russian lathes prioritize robustness and accuracy.

A comparative analysis by the Global Machinery Review highlights the following:

- Russian lathes offer superior durability compared to European models.

- They match the precision of Japanese lathes but at a lower cost.

- They outperform Chinese lathes in terms of build quality and longevity.

The Market for Russian-Made Lathes

The market for Russian-made lathes is growing, driven by increasing demand for high-quality, durable machinery. Export figures indicate that Russian lathes are gaining popularity in emerging markets, where cost-effectiveness and reliability are key considerations.

According to the World Trade Organization, exports of Russian lathes have increased by 15% annually over the past five years, highlighting their growing global appeal.

Key Market Segments

Some of the key market segments for Russian lathes include:

- Developing countries seeking cost-effective solutions.

- Industrial sectors requiring heavy-duty machinery.

- Small and medium enterprises looking for reliable equipment.

The Future of Russian Lathes

The future of Russian-made lathes looks promising, with advancements in technology and increasing global demand. Manufacturers are investing in research and development to enhance the capabilities of these machines, incorporating cutting-edge technologies such as AI and IoT.

Experts predict that Russian lathes will continue to evolve, offering even greater precision and durability while maintaining their competitive pricing. This trajectory positions them well for continued success in the global market.

Conclusion

In conclusion, Russian-made lathes are distinguished by their unparalleled precision and durability, making them a top choice for industrial applications. Their rich history, advanced features, and versatile applications ensure their relevance in today's competitive market.

We invite you to share your thoughts and experiences with Russian lathes in the comments below. Additionally, feel free to explore other articles on our site for more insights into industrial machinery and technology. Thank you for reading!